News at the HPC²

Creating Original Algorithms for Calculating Approximate Solutions to Complex Problems

June 27, 2019

Doyl Dickel and Sungkwang Mun disucss calculations.

Photo by Beth Newman Wynn

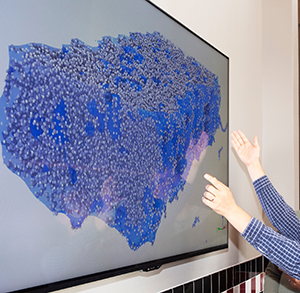

Photo by Beth Newman Wynn

A key feature of today’s computational models is that they are able to help scientists study biological and non-biological material systems at multiple levels, but the models run separately, they are not programmed to interact due to the distinctively different characteristics in each system. Thus scientists can’t predict how inorganic composites and organic molecules interact. For instance, there is the case of how a biological implant made of various polymer and metallic materials would connect with the organic cells in the body.

“Our goal is to develop a universal formalism to create a computer simulation that will one day improve the treatment of dangerous reactions to medical implants. Giving the researchers the ability to combine and witness a variety of composite systems with all the atoms connecting in one simulation,” Dickel said. “They will see the titanium plate, the polyethylene that is sort of holding it in place, the organic cells and fibers that are growing onto it and they will see how it all works together and exists as one coherent computational simulation.”

The computational capabilities at Mississippi State’s High Performance Computing Collaboratory have vastly expanded, which enables Dickel and Mun to develop new and sophisticated mathematical formulas that can reveal the nature of foreign body responses.

The computational capabilities at Mississippi State’s High Performance Computing Collaboratory have vastly expanded, which enables Dickel and Mun to develop new and sophisticated mathematical formulas that can reveal the nature of foreign body responses.“We are using the Modified Embedded Atom Method that is used to simulate metallic systems as a base model equation to create and merge with our organic materials method,” Mun explained. “We are trying to provide the calculation software as well as the development kit for their own research problem.”

The MEAM formalism, developed by Michael Baskes, a Mississippi State research professor, has become very popular for the metallic system since its initial launch years ago. Mun and Dickel are working to extend this method to include polymer and organic material as well, which requires modifications to the original equation to distinguish between the different compositions of the metal polymer and organic systems.

“Our goal is that researchers will be able to create their own recipes and run their own simulated experimentations to create and test new products as a result of using our universal formalism,” Mun said.

The idea with simulation is computational models can sample the same 10,000 things in the 10th of the time for a thousandth of the cost and has the ability to reveal the final five simulations that should produce the results expected when actually building the experimental tests.

Dickel explained, “When it is at its most optimal, computational simulation is not cutting just half the cost and time, it is 10 to hundreds of thousands of times cheaper if you can trust the model. That is what we are doing is making sure that the things we predict reflect the true underlying physics.”

Written by Diane Godwin